This article originally appeared in Southern Exposure Vol. 10 No. 1, "Who Owns Appalachia?" Find more from that issue here.

Most boys become apprentice on account of the action goes on around the blacksmith shop like beatin' on the red hot iron, the sparks fiyin' and the kids like that. I stand at the door and watch the sparks. I said I would like to be a blacksmith some day.

- Philip Simmons

In 1925, when Philip Simmons made his decision to take up blacksmithing, there was no shortage of available role models in Charleston, South Carolina. The waterfront district was thick with craftsmen, and included several blacksmith and wheelwright shops. Within one five-block area, four Afro-American ironworkers plied their trade. The tradition of blacks in skilled trades in Charleston goes back to before the 1 740s, when slaves regularly hired themselves out as craftsmen. The profits they earned were split with their owners, and some slaves eventually found the means to buy freedom for themselves and their families. The pattern of white patronage of black skill was so entrenched that even after Denmark Vesey's abortive revolution in 1822, which caused Charlestonians to regard all blacks with great fear and suspicion, black craftsmen were still able to earn a respectable living.

Just as it was normal for a boy raised on a farm to do farm chores, so too was it natural for Philip to go into blacksmithing. Although born on Daniel Island and raised by his grandparents, he spent most of the school year across the river in Charleston with his parents; he finally moved to the city permanently at age 13. By then he had spent years walking among some of the most elaborate and well-executed examples of the blacksmith's art. His fascination with wrought-iron design developed further in art class in school. When he finally decided to become an ironworker, he turned to a neighbor who worked just two blocks away. At age 70, Peter Simmons - the Old Man, as Philip called him - took on another apprentice, his last. But like many boys first attracted to the "action of the shop," Philip's commitment was not immediate:

You know how a boy is. Thirteen years old boy then, they full of pep and that particular time I wasn't too serious then. Go on the baseball diamond, play ball a while and come back over in the shop. Go cross the street and go down to the shoemaker's shop and talk to the man repairing shoes. Go down to the f oat of the wharf and talk to the people who bring boats in with vegetable and shrimp and fish, seafood. And that thirteenth year is kind of a year of action for me. After the thirteenth year, then I got kind of serious in the blacksmith shop. You know, six, seven, eight months after that, settle down.

Philip's explanation for his success is simple: he stayed, therefore he learned. Disguised in this equation is his attraction to the craft, his appreciation of the drudgery and long hours of physical and mental labor required, his own skill and the careful direction and strict discipline given by his teacher, who had himself learned the trade from a stern teacher, his father Guy Simmons. According to the stories told Philip, Peter's "daddy used to turn the back of the hammer and hit him on the head or shoulder .... He [Peter] didn't hit me on the back of the hand, but his daddy done it to him."

Philip describes his four-year apprenticeship as a long training experience:

I was going and clean the shop up and go on errands for him, you know. Go out and get things and finally I would stop and spend hours in there cleaning and sweeping the shop .... He could use a boy. Hold the horse while he puttin' the shoe on. Turn the forge. He had hand forge then. We call it bellow, bellows. Turn it with hand .... He'd give me a few pennies, maybe a quarter. After knowing my way around, where the broom is to clean the sh0p and some of the tools, he got interest in me. He hire me at a dollar and a half a week. When I start getting four dollars a week, I was there three or four years .... [By] that time I'd know my way around pretty good. I could straighten iron, heat 'em and bend 'em myself The Old Man 'd step out the door and say, ''Bend it, it's in the fire, hot, turn it." That's when I got eager to learn the trade, when I could do things on my own. So I would get me a little practice. So there it is. As he would get confidence, then he would launch out the bigger things or more particular thing. When I make a mistake, he would stop everything. Some people will tell you you ’re wrong and keep going working. He stop everything and explain it to you.

Because Peter Simmons worked in all branches of smithery, he handled a wide range of jobs for an equally broad range of customers, from city dwellers to Sea Islanders, repairing wagons for urbanites and plows for farmers, shoeing horses and making anchors, rudders, hooks and other ironwork for the ships along the nearby wharf. In learning to be a blacksmith, Philip also became familiar with the full range of business activity in the Charleston area. At age 19, he had to assume full responsibility for the shop because Peter “took sick and went into the hospital” for two months. Peter returned to find Philip a trained and tested blacksmith. For four more years, Peter maintained control of the shop , but with a full partner; he was still the boss, or as Philip notes, “he called the ball and strike.” But in the early 1930s, Peter moved across the river to the town of Mt. Pleasant, where he continued to run a small blacksmith shop. Philip Simmons, 23, embarked on his career as a master craftsman with his own shop.

During this period, there was a marked decline in the number of ironworkers in Charleston and elsewhere. Most blacksmiths closed their shops down and sought other occupations. Some retired; others moved north. Philip received his first inkling of the precarious position of the old-timey trade while still an apprentice. “I feel kind of skeptical,” he recalls, “after people coming around talking about the wagons are going out. No wagon. You know what that mean. No horse. No wheels to repair or build. Then what I goin’ do?”

But his fears were calmed by Peter’s advice: “The Old Man say, ‘Boy, don’t worry.’ He say, ‘There’ll always be work here for a blacksmith. Don’t worry about it.’” Sure enough, the Old Man was right. The first trucks were essentially set on a wagon frame and needed the same body work and refinements that Peter and Philip had done for dozens of wagons. “Same principle, same identical thing,” says Philip. “You know the blacksmith trade give you so many idea about other trade in iron now, like the ornamental ironworking or the angle smith or the automobile shop, the automobile builder, and building truck bodies. You see the blacksmith shop is the father of all those trades.”

Philip’s own entry into the decorative field of ironwork was gradual:

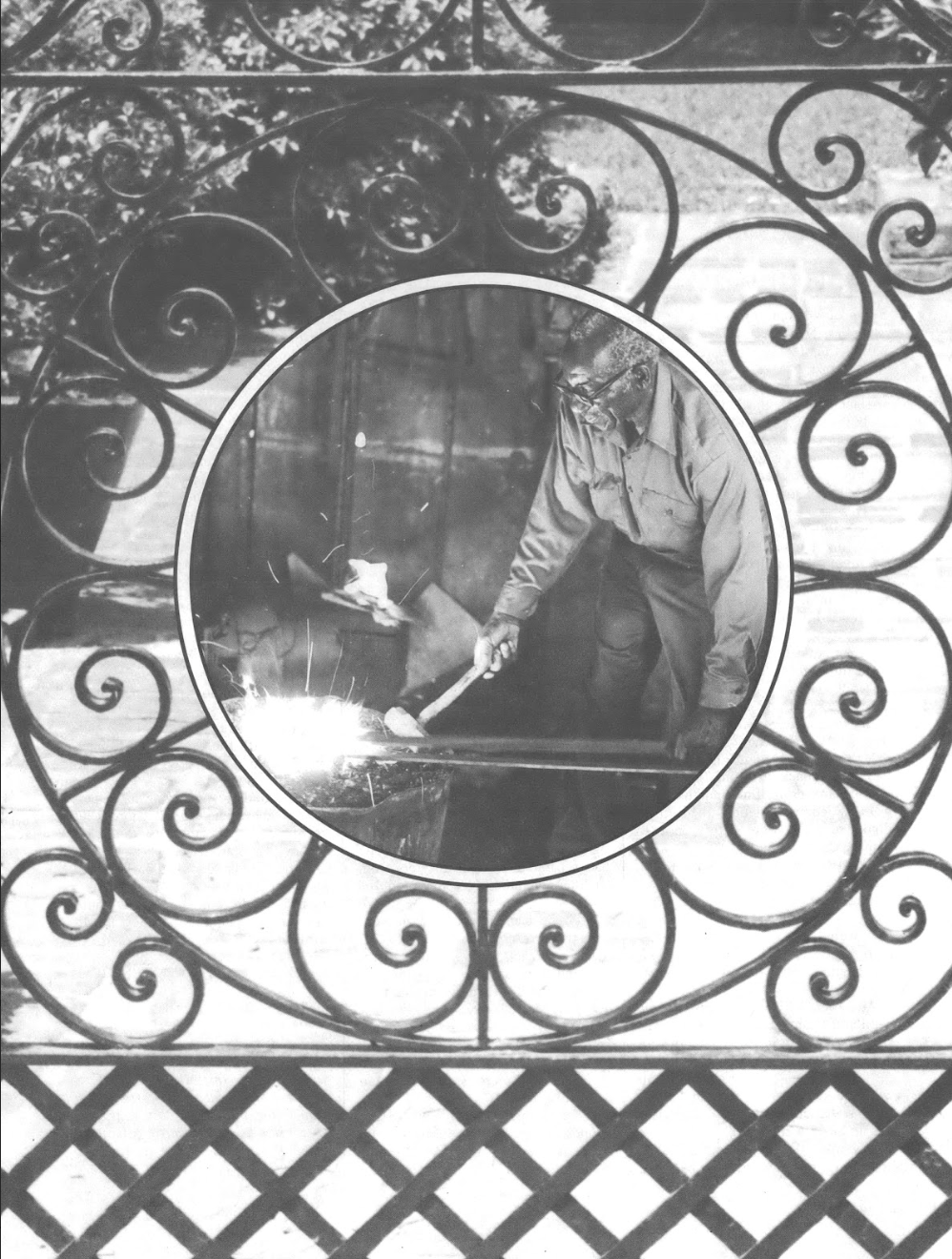

And after the horse-buggy wheels go, something come to me. Say, “You a blacksmith, you can bend those iron just like most pattern. You could do a better job. You could make it look like the old originals cause you got your forge. ” When I got on the forge and people come in, “Mr. Simmons, I got a broken place in my gate. Could you repair it?” I go there and repair it. Didn’t have no electric drill. You take the hand drill and rivet. Had [to] rivet them scrolls in. It was hard riveting them. And finally I work and I keep my pride, do my work with pride. Finally I start with one piece, repairing gate. Then start making the parts to put in ’em, like the man got down to the Sword Gate. Finally, I start making the whole gate. I said, "I got the forge and I turn ’em out like the old original." Finally people going for that stuff. “Go ahead and make it like that. That’s what we want.”

He [Peter Simmons] didn’t do too much ornamental work, but after I took over then I went into it forcibly. Well, I found myself into it all the way until today.

There’s a big demand for iron gates, big demand now. There’s always gonna be for that type of work: iron gates, window grills, porch railings, and columns. As long as they gonna build a house, they gonna put iron on it in Charleston. ’Specially in Charleston.

Philip Simmons estimates that in the 40 years since he first took a decorative commission, he has turned out more than 200 gates. He has also made balconies, stair rails, window grills and fences. The pages here feature photographs of some of his typical works, along with his comments and general descriptions.

Because the right balance between openness and closed-ness only emerges from the process of design and fabrication, Philip’s creation of decorative wrought-iron works is essentially an example of experimental composition. He has the outline of his work which he then fills with ornament. The “move to fill in” begins with an almost tedious freehand drawing, which after years of experience closely follows the scale of his measurements — usually one inch represents one foot. Scrolls and leaves are sketched out in pencil, evaluated, erased and redrawn — often in the same place. This stage of design may last a few hours or a few days, depending upon the complexity of the commission and the urgency of the job.

When Philip Simmons finishes a gate he has satisfied himself, his client and Charleston’s sense of history. Most contemporary artists sense little social restraint upon their works, but in the creation of ornamental ironwork in Charleston the direct influences of the community are inescapable. It is important to remember, however, that the decision to repeat the old, the commonplace, the typical, the usual, can be as significant as an innovative choice. Tradition is kept alive by a series of deliberate, rational decisions. It does not survive without talented, committed performers. Philip’s own creative process involves improvisation within the context of a community inspired by its history. Clients come to his shop with full confidence that whatever he makes will not only be of high quality, but appropriate for Charleston.

I asked them, I say, “You got it in mind of anything you want?” “No, I want you to design it yourself. And just what you make, I’ll know I’ll like it.” I go ahead.

Guy said, “Here, this is what I want, Mr. Simmons. I got a staircase. It’s inside, this is not outside. I want spokes but I don’t want it all spokes. Want two sets of decoration. Suppose you put one here, Mr. Simmons, and one up here. Then you can go. ahead with your spokes. Leave that opening in there. Now put something fancy on there. What could you put in there for me?” I say, “O.K., let me think, think of something. ’’All my ideas gone.

But what I would do was put this on paper, then I’ll take it outside and III put several [designs] in there. I go ’head to my work and don ’t just try to bump my head to tell him what I can do. Don’t think about [it], just go ahead. I come in the evenin’, I’ll lay down in the bed. Visualize it. Then [at first] things divided in your mind. Then you don’t see too many [options]. But I come up with something. . . . I had to stop and think. Have to wait. I have to clear up, what you call it, the air traffic. When the plane come in and can’t land and he say, “Fly around. ” Then he’ll tell the passenger on the plane, “We’re waitin’ till the air traffic clear.” Well, you have to wait till that traffic clear up on my mind. . . .

No, I don’t dream about it, but I have a vision. I have a tremendous vision. Every so often it comes over me. I never dream about it. I get a tremendous vision every so often. I’ll visualize something. I never forget about it. I see it finished completely in my mind.

When Philip speaks of receiving “visions,” they are more than individual inspirations. His use of a supernatural image is in fact a perpetuation of a metaphor in widespread use in American and Afro-American culture. West African mask carvers often claim to dream the mask before they sculpt it. Among the Gola of Liberia, for example, it is believed that an artist’s spiritual guardian or jina provides him with the genius (neme) to create a good mask or statue. The Gola people often characterize their carvers as dreamers. The manner in which Philip receives inspiration, his conceptual process, allows us to see his works as simultaneously part of Charleston’s ironworking tradition and set within the long history of Afro-American art.

Today, as he teaches the processes of forge welding, upsetting, punching, riveting and other handwork aspects of blacksmithing to his apprentices, Philip Simmons recreates the phases of his own training, reaffirms his ties to the community and renews for another generation the traditions of a venerable craft. His influence on his apprentices can even be seen in the terms they use and their methods of “visualizing something.” For example, Silas Sessions, who began as a helper with Philip at age 12 and who is now a full partner in the shop, talks about his creative process:

Normally customer want a gate - we draws three or four, five different kinds of gates and let him look through and pick the kind he wants. Whatever one he choose, that’s the one we have to make him. You know when I be home, I go to bed at nine o’clock. I probably wake up about 12, cannot go back to sleep so I get some paper and pencil and I start drawing and pretty soon I go to sleep. I may not finish my drawing that night, but maybe the next night I finish the drawing.

Philip’s most recent apprentice — his last, he says — began at age 29 after studying art in high school and working at many jobs, including as a welder in the shipyard. After 13 months as an apprentice, Willie Williams says he can “see the reward”:

When I first came into the trade or the art I was willing to do it for free. You know, come around after work and do it for free. This is how bad I wanted the art because I noticed this was something entirely different from the line of work that I been doin’. It was a chance to express my inner self. Like I said, it’s good to know how to read a ruler or do mathematics or weld steel together or burn steel, but it’s another thing to design - stuff like that, create your own things. This is what I enjoy. Just being able to come from my mind and put it into reality. This was the chance in a lifetime and each [ time] that I’m around I feel that I’m coming closer and closer to harvest.

One of the main things is you take iron or metal. It’s the hardest thing in the universe. But once you heat it, it becomes one of the softest things in the universe. Then you can shape it. It’s just like being the god over a piece of iron or something. Even though I know I’m not God, it’s just being able to take something from nothing and turn it into something beautiful. Create something from nothing which I think is remarkable. Pick up an old piece of metal, old rusty metal just laying around. And throw it in the heat, bang it a few times, and here you’ve got a chisel. Something that you can go out and make money with. This is what I think is remarkable about the trade: making things or making the iron bend to your will.

I consider this my only profession even though I have a part-time job at the hospital. One day, hopefully, I can give all other work up and just apply myself to just this one thing. I feel somewhat of an artist. I feel I belong to more than a blacksmith. Just a thing that I want to do.

In a chain running from a distant ancestor to Guy Simmons to Peter to Philip to his apprentices, the links are joined; the tradition of Afro-American work is preserved and revitalized. “Most think blacksmithing is a dying art, but it isn’t,” says Philip. “I feel confidence now and I know pretty good about iron, but I still learning, after 50 years. Fifty years ago and today — to me it’s no different. I’m still heating and bending iron.”

Tags

John Michael Vlach

John Vlach directs the folklore program at George Washington University and is the author of The Afro-American Tradition in Decorative Arts. His superb book of photography and description of Philip Simmons’ work, Charleston Blacksmith, was published in 1981 by the University of Georgia Press. (1982)