This article originally appeared in Southern Exposure Vol. 8 No. 1, "Building South." Find more from that issue here.

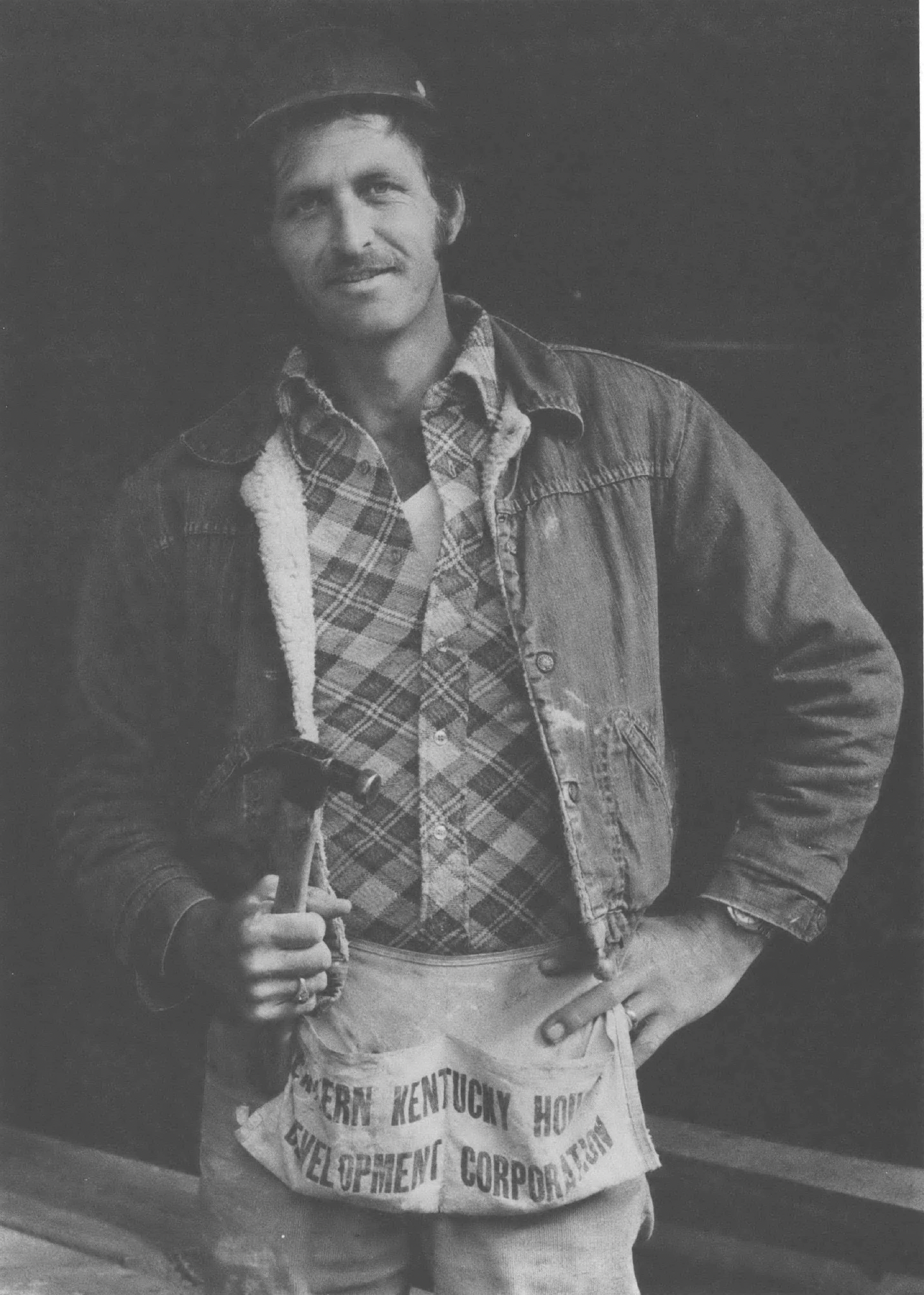

Appalachian Kentucky has so many housing problems that volumes can be written trying to describe them. One easy way to sum up the problems is to say the area does not have enough Tom Mosleys.

Seventy-six-year-old Mosley has been building houses ever since he could get a good grip on a hammer. His friends say he has built more homes in Knott and Letcher Counties than any other man even though he took some years off to mine coal.

Despite the hard work and skill, when Mosley reached retirement age, he was still losing the battle against housing blight. He did not need the Census Bureau to tell him that a full 50 percent of Letcher County’s 8,620 homes were substandard, that over 60 percent of them were worth less than $5,000 and that 51.8 percent were built before 1930.

In 1968, at age 64, Mosley began working as a crew leader with the East Kentucky Housing Development Corporation (EKHDC), a federally funded non-profit home repair demonstration program that hires unemployed elderly men to repair houses of the poor.

EKHDC began and continues as a demonstration that solutions to unique rural housing problems can be found by local people, and that institutions to fill needs — including the hiring and training of the unskilled and unemployed — can be built at the local level. Founded by Pat Gish, now the executive director, EKHDC is operated by a 12-member board which acts on all major policy matters. The board includes representatives of the poor, local government, business and other civic interests.

EKHDC is the only agency in central Appalachia which has as its prime objective the creation of adequate housing for the rural poor. While EKHDC has become the model for the Community Services Administration (CSA) national home repair program, the program does not claim to be the answer to all rural housing problems. It believes, rather, that its experience has demonstrated that there have to be specially tailored answers designed at the local level and backed by flexibility in regional, state and federal housing assistance programs.

By 1973, Mosley and other crews like his had repaired 2,193 of the most dilapidated homes in a four-county area. They had fixed leaking roofs, underpinned shacks, repaired hazards like faulty porches and steps, added water and plumbing facilities — in short they had given livability to homes that otherwise never would have been repaired.

What pleases Mosley most is that the project has trained unemployed and unskilled men - many, like him, former miners with black lung disease — in new skills that are desperately needed throughout Appalachia. “When these men first started out, some could drive nails,” Mosley reflects, “but most couldn’t do much else. Now some of our men have become good drywallers, joiners and roofers. Some of the boys are now out on their own.”

So far, EKHDC has repaired the homes of over 3,500 poor families.

Woodrow Sizemore is the first to admit that he enjoys an occasional prank. His favorite one lately centers around EKHDC’s modular home building program, which he heads. It goes like this: ‘Teople will be driving to work really early in the morning and see me coming up the hollow with a crew and some trucks. That usually arouses some curiosity, but nobody says nothing. But then when they come back in the evening, I’ve got a house sitting there. They stop dead in their tracks every time — even if it’s on the blacktop — to see what’s going on.”

What Sizemore is describing is EKHDC’s answer to the absence of construction firms in eastern Kentucky willing to build new homes for lowincome people. Like the program’s home repair project, modular home building had modest beginnings that capitalized on the talent and labor of eastern Kentucky people working to find solutions to housing problems. Low-income persons are able to purchase these quality homes, designed for the eastern Kentucky environment, for $23,030. The homes are an answer, not only to mobile home living, but to the costs of custom home building that builds homes only the rich can afford.

The project’s housing factory, which is now capable of turning out components for two houses a week, is located in an old machine shop donated by a coal company. The components are made and the homes erected by men who qualify for assistance under Department of Labor employment programs.

Modular home building can be a complicated process to understand until you hear an explanation from Lewis Smith, who runs the housing factory. “It’s no big thing, really,” he suggests. “All you do is just do the same old thing over and over again.”

The “thing” that Smith and his crew of 19 repeat in the converted mine shop is building housing components — a utility core (which includes the kitchen and bathroom and all plumbing and electrical facilities), wall panels, floor panels, roof trusses and other pieces that can be put together in a plant setting.

While Smith is unduly modest about the work at the factory, he is right in saying, “The worst problem is to find a place to put the houses we build. There’s plenty of land; it’s just turned the wrong way — up.”

It’s no exaggeration to say that it is easier in Appalachia to meet the federal requirements to open a coal mine than it is to meet the federal requirements for home building sites in rural areas. Coal mining regulations are tailored to meet local mining conditions; home siting regulations are concrete-hard in insisting that the mountains be made low and flat before houses can be built. Needless to say, it can’t be done. “People find a site for a house, then it takes six months to get it approved — if ever,” Smith complains.

Despite siting problems, Sizemore has erected 180 houses, including 32 houses in one site at Sanctified Hill, a Harlan County community that was destroyed several years ago by a slide.

Getting the home building program going was not so simple for the staff in the beginning. After the home repair business was running smoothly, they began to look for ways to meet the other mandate given by the Office of Economic Opportunity, the federal agency that initiated EKHDC in 1967: develop a durable housing industry in eastern Kentucky which would fill local needs with capital and subsidies provided from federal resources.

Considerable effort was spent in developing a rent-supplement project to house 50 low-income families, but after three years of negotiations, plans and surveys, the Department of Housing and Urban Development killed the project because site development costs for the project’s hillside site (the only kind available) were higher than HUD guidelines allowed.

During the negotiations for the rent-supplement project, it became obvious to everybody concerned that eastern Kentucky had no construction firms interested in building for the low-income market and in building a home which would meet mountain people’s needs and desires. Faculty and students from the Yale School of Art and Architecture who worked with EKHDC urged that some way be found to use modular or panelized structural techniques because of the limited number of skilled craftsmen and builders in the mountain area and because a “housing factory” could conceivably be used to further the economic development and job training goals of EKHDC. With the help of the architectural consultants, EKHDC designed its system of industrialized housing, using low technology so that unskilled workmen could be trained to build standard new homes that both reflect the lifestyle of mountain families and meet the minimum property standards required for financing by federal housing subsidy programs.

In 1971, OEO gave permission to use some unspent funds for construction of an experimental house using the industrialized housing system EKHDC had designed. The panel system for the house and the rudiments of a factory were constructed at a donated building near Neon. With funds from OEO’s Housing Manpower Demonstration Project, EKHDC began producing the components that other EKHDC crews use to build houses for low-income families.

EKHDC operates in four counties — Leslie, Knott, Letcher and Perry — referred to as the LKLP area. They are part of the region termed “central Appalachia” — the hard core of the Appalachian problem — and most of the recent improvements noted in economic and social conditions in other parts of Appalachia by and large passed them by. Although the coal industry, which is the principal employer in eastern Kentucky, has enjoyed boom times in recent years, there are still thousands of low-income families without adequate housing, and indeed many middle-income families are living in poor housing. In Leslie and Knott, over 50 percent of the people live below the poverty line. Overall in the LKLP area, 38 percent of the residents — 31,282 people out of 80,873 — lived in poverty in 1977.

The housing problems of eastern Kentucky are among the worst in the nation. The Appalachian Regional Commission says that problems of overcrowding and substandard housing are “the most severe” in the Central Appalachian subregion, of which eastern Kentucky constitutes a major part. The rate of combined incidence of overcrowding and substandard housing is about seven and a half times the average for the nation, according to the ARC.

The U.S. Department of Agriculture Economic Research Service, reporting on housing conditions in areas served by the Farmers Home Administration housing programs, singled out Kentucky and Mississippi as the states with the greatest housing needs in terms of relative incidence of bad housing, noting that in these two states 37 percent of all housing in FmHA’s area lacked plumbing or were overcrowded.

Surveys by the University of Louisville and other researchers confirm that eastern Kentucky is the center of Kentucky’s housing problem. In a 1979 study, the University reported that 21 eastern Kentucky counties had the fastest-rising rate of new households in the state, adding 75,000 between 1970 and 1978. In those same years only 16,500 new single-family homes were built, 55 percent of them mobile homes. Spindletop Research of Lexington notes that “by comparison the non- Appalachian portion of the state appears to be modestly well off in housing quality.”

Of the total 25,100 housing units in the four counties, 13,647 are classified as substandard. That is, they lack some or all plumbing facilities, or they are occupied by more than one person per room, or both. Of the total substandard units, 11,396, or 83 percent, both lack some plumbing facilities and are over-crowded.

Of the total 13,647 substandard housing units, 10,412 — about threefourths — are occupied by families with annual incomes of less than $5,000 a year. Nearly 40 percent of these houses are valued at less than $5,000.

Lester Gibson has the fastest clutch foot in eastern Kentucky, which comes in handy when he is trying to navigate a 100,000-plus-miled Chevy truck uphill on a road that is really a creek bed.

Gibson travels roads worse than that every day as he visits the four crews — a total of 12 men — that he supervises in Letcher and Knott Counties. His fantasy is to some day be able to bounce a whole truckload of federal housing bureaucrats up one of the creekbeds to see where they would put the curbs, culverts and sewer pipe that they always require for federal housing aid.

As a 10-year veteran with EKHDC, Gibson has seen some of the worst housing in rural America. “I’ve worked on so many houses that were so pitiful, I can’t even think of the worst one,” he said recently. “I’ve seen homes with the windows out in winter, with the bedposts sticking through the floor and with the roof falling in.”

His carpentry experience was limited when he started with the program as a crew leader of seven men. “I had helped build my own house, but that was about it,” he says. Since then he has watched trainees rise to become crew leaders, with some leaving to work with private contractors.

Ninety percent of the men he supervises and trains are over 60. Many have coal mine-related disabilities, including black lung disease. Only a few have what he calls “rough carpentry experience.”

In addition to supervising and training, Gibson’s job includes visiting homes to help owners determine repair work and its cost after their application has been approved. He helps the owner find materials at the cheapest cost, which sometimes includes salvaged lumber or tin.

He then assigns a crew to complete the job. Gibson couldn’t agree more with his crew leader, Garlan Huff, who migrated back from working in Ohio, when he says, “This program has benefited more people down to the nitty-gritty — real poor people — than anything else ever to hit these mountains.”

Tags

James Branscome

James Branscome is a free-lance writer from Sevierville, Tennessee, who contributes to The Mountain Eagle, The Washington Post and other publications on a wide variety of Appalchian topics. (1980)

Jim Branscome writes regularly on life in Applachia and is a staff member of Highlander Center in New Market, Tennessee. (1974)