This article originally appeared in Southern Exposure Vol. 7 No. 4, "Tower of Babel: A Special Report on the Nuclear Industry." Find more from that issue here.

In 1942, the Manhattan Project sent out a team of engineers to determine the sites for the production plants that would build the Hiroshima and Nagasaki bombs. In 1950, when Harry Truman ordered the Atomic Energy Commission to proceed with the production of the hydrogen bomb, the Army Corps of Engineers was dispatched to select the new production sites. These were awesome events, both in the history of armaments and the history of humankind. In each case the Manhattan Project and the AEC directed their engineers south to survey for possible sites.

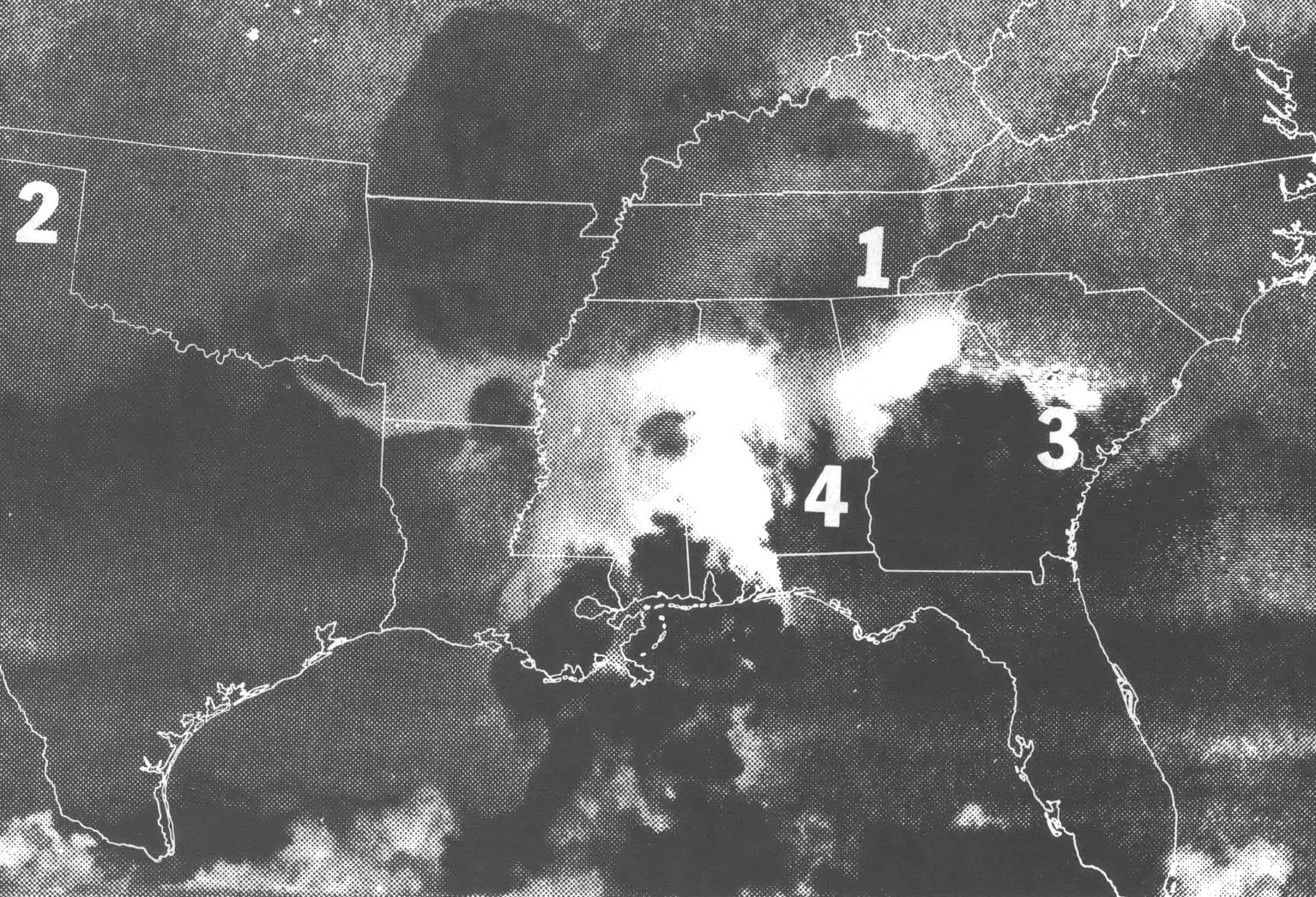

As a result of those surveys, four out of the seven operating nuclear warhead production facilities are now located in Southern states. And in recent years, more and more of the production capabilities outside the South have been transferred to these four plants. Each day these facilities produce three new warheads for the U.S. arsenal.

From the grasslands of South Carolina to the farmlands of the Texas panhandle and from Florida’s Gulf Coast to the Cumberland Mountains of east Tennessee, Southern communities, workers and natural resources are essential to the production of each warhead and bomb in the U.S. nuclear arsenal. For instance, each hydrogen bomb contains a neutron generator which bridges the gap between the bomb’s trigger and its fusion explosion. In order to manufacture these generators, the Oak Ridge Y-12 Plant in Tennessee supplies lithium fuel cores to the Savannah River Plant in South Carolina. There the lithium cores are placed in nuclear reactors. The process produces tritium. The tritium is transported to the Pinellas Plant near St. Petersburg, Florida, where it is fabricated into the neutron generator. The finished component is then sent to the Pantex Plant in Texas for the final assembly of the warhead.

The fusion fuel for U.S. nuclear bombs is a compound of lithium and deuterium (heavy water). The deuterium originates in the water of the Savannah River. At the Savannah River Plant’s heavy-water separation facility, the deuterium is isolated from the river water. It is shipped to the Oak Ridge Y-12 Plant where it is combined with lithium, fabricated into a tablet shape and sent to the Pantex Plant in Texas.

The fission trigger of each nuclear warhead originates with plutonium produced in the reactors of the Savannah River Plant, and uranium 235 components which are machined at the Y-12 Plant in Oak Ridge. The triggers are fabricated at the Rocky Flats Plant near Denver, before they are sent to Pantex for assembly. Fission triggers, fusion fuel and the neutron generator which binds them together are the essential components of a thermonuclear explosion. Each of them is fabricated and assembled in production facilities in the South.

In each of these four Southern communities that host nuclear weapons production facilities, there is a public climate of secrecy and avoidance. Workers will insist, “We don’t make the bomb, we just build the parts for the bomb.” Each month in Oak Ridge, a new message goes up on the company billboards around town. The messages tell of the promise of nuclear technology or they remind workers of the national security requirement for secrecy. At the Pantex Plant a poster picturing a woman wrapped in a blanket reads, “Security is a blanket responsibility.”

The Carter administration has proposed a $500 million program to modernize the nation’s nuclear weapons facility complex. The major focus in the upgrading will be the Oak Ridge Y-12 Plant, where some 43 percent of the facilities were labeled “poor and/or inadequate.” Pantex will also receive substantial attention from the upgrading program. Last year Herman Roser, the plant’s manager, testified in a Congressional hearing that he believed the plant should be completely replaced. He said of Pantex, “We have come to the conclusion that it doesn’t meet the latest safety and safeguard criteria.” The Savannah River Plant, which also will be remodeled under the program, was called a situation of “galloping obsolescence” in a House Armed Service study.

Other Southern facilities also support the national weapons program. Southern port and shipbuilding facilities in Newport News, Norfolk, Charleston and Pascagoula handle nuclear wastes created by the Navy’s nuclear fleet of submarines, carriers and destroyers. And, though the federal government is officially silent about such information, it is common knowledge among workers at the Nuclear Fuel Services Plant in Erwin, Tennessee, and the Babcock and Wilcox Plant in Lynchburg, Virginia, that the fuel cores they produce propel this nuclear fleet.

These facilities pose their own significant threats to the health and safety of workers and the surrounding community. On April 14, 1979, 288 employees of Nuclear Fuel Services — represented by the Oil, Chemical and Atomic Workers Union — went on strike to protest the numerous health and safety dangers at the Erwin plant. Shortly after the workers returned to their jobs, plant officials notified the NRC that they had misplaced a large quantity of enriched, bomb-grade uranium, which could have escaped into the local area and presented a severe threat to the local populace. No explanation for the missing uranium has yet been offered.

Over the last five years, nuclear warhead production facilities in other parts of the country have been closed down and their functions moved to plants in the South. The Hanford Plant in Richland, Washington, which once produced plutonium along with the Savannah River Plant, has turned its production function over to the South Carolina plant. A plant in Burlington, Iowa, which assembled nuclear warheads was closed down in 1975. All the assembly functions are now carried out at Pantex. There has also been a proposal that the Mound facility, near Dayton, move its plutonium and tritium detonator production to the Savannah River Plant. Under pressure from citizens in Colorado, the Department of Energy announced earlier this year that it would conduct a study of the feasibility of moving the Rocky Flats Plant. One of the first options to be suggested for a relocation site was the Pantex Plant.

All this means that increasingly the burdens and risks of nuclear weapons production are being shifted to existing facilities in the South. The benefits are obvious: these plants employ 17,053 people. But these jobs must be weighed against the risks of nuclear warhead production, keeping in mind the option of job and industrial conversion.

The four major Southern weapons plants, and other weapons-related facilities, present their communities with the risks of radiation contamination. The workers are required to work with some of the most hazardous substances in existence in facilities that are recognized to be obsolete and unsafe. Municipalities and state taxpayers must carry the burden of the federal government’s tax-exempt status. Jobs and livelihoods become dependent on the dictates of national security. Land and natural resources are diverted from serving the local needs. By using federal funds to experiment in such fields as waste solidification, some of these facilities — Oak Ridge and the Savannah River Plant in particular — further the public subsidy of the commercial nuclear industry. And finally there is the moral dilemma that arises when one region of the country is required to accept more than its share of risks and burdens on behalf of a national policy of preparation for nuclear war.

Description of the Key Facilities

1. Oak Ridge Y-12 Plant

Date built: 1943.

Location: 25 miles west of Knoxville, Tennessee. One thousand families were forced to leave the farming area for eight years while the government built its top-secret facilities.

Operator: Union Carbide.

Employees: 5,237; 1,487 work on enriched uranium projects.

Union representation: 17 unions bargain jointly through an Atomic Trades Council. The largest, the International Association of Machinists and Aerospace Workers, represents over half the workers.

Functions: Originally used by the Manhattan Project to produce the uranium 235 for the Hiroshima bomb. Today the “bomb plant,” as the first workers called it, fashions highly enriched uranium and lithium deuteride components for warheads. In addition, a uranium enrichment plant and research laboratory are located at Oak Ridge and operated by Union Carbide.

Comment: A shroud of secrecy and “company town” aura still envelop the Oak Ridge area. Public meetings are monitored and public dissent is frowned upon. All plants are owned by the federal government. Neither Union Carbide nor the Department of Energy are required to pay local property taxes. Keith Bissel, the mayor of Oak Ridge, recently commented on his city’s inability to collect taxes from the Department of Energy: “We have three major plants here — Y-12, X-10 and K-25 — worth two billion dollars. . . . Our city has the highest tax rate of any city in the state due to the fact that we have these three plants. I don’t want to bite the hand that feeds me [he works for Union Carbide], and I’m proud of these plants . . . but they don’t pay a damn cent in taxes. They only pay two million dollars in lieu of taxes.” If the Department of Energy paid taxes at the same rate as other property owners in Oak Ridge, the tax bill for the three plants would amount to over $140 million a year. (A recent re-evaluation in property values has doubled the value of property in Oak Ridge and has meant a lowering of the tax rate. Oak Ridge no longer has the highest tax rate in the state. But, since the value of the DOE property has also doubled, the figures projected here for its tax payment are still correct.)

2. Pantex Plant

Date built: Originally built in 1942 to make conventional bombs; closed after World War II, reopened by the Atomic Energy Commission in 1951.

Location. 23 miles northeast of Amarillo, Texas.

Operator: Mason and Hanger-Silas Mason Co., Inc. (a Kentucky-based engineering firm that built New York’s Lincoln Tunnel).

Employees: 2,016.

Union Representation: Half the workers are represented by the Amarillo Metal Trades Council, which consists of several trade unions including the International Association of Machinists and Aerospace Workers.

Functions: Final assembly plant for every nuclear warhead and bomb in the United States arsenal; also produces conventional explosives for nuclear weapons and disassembles and repairs retired warheads and bombs.

Comments: A similar facility in Burlington, Iowa, was closed down in 1975. In March, 1977, Pantex machinists Ray Tucker, Chester Grimes and Ray Hendershot were killed when a piece of chemical explosive detonated 42 3Mp while Tucker was shaping it on a lathe. “Workers regard the bombs like beautiful pieces of furniture,” says Dorothy Moore, an employee on the assembly line at Pantex. “You wouldn’t believe it was so destructive.” Leroy Tillery of the Amarillo Chamber of Commerce says, “I don’t really know what they do out there. I think that helps. Nobody really is concerned about it because nobody really knows what’s going on.”

3. Savannah River Plant

Date built: Begun in 1950, completed in 1956.

Location: 300 square miles covering portions of Aiken, Allendale and Barnwell Counties, South Carolina. The Savannah River forms the plant’s western border for 27 miles; the site was selected from 114 alternatives primarily because of its abundant water supply and “sparse” population. One thousand families, mostly black sharecroppers, were removed from the land during construction. In 1972, the entire site was declared a National Environmental Research Park.

Operator: E.I. DuPont de Nemours & Co. designed, built and now operates the facilities under a “no-fee” contract allowing DuPont to recover its cost of operation plus a “reasonable” profit.

Employees: 8,599; 4,900 people are involved directly in producing nuclear warhead materials. Another 2,400 construction workers are building new storage tanks.

Union Representation: None.

Functions: Five nuclear reactors (three currently in operation) produce tritium and plutonium for nuclear warheads. Plutonium is retrieved by two reprocessing plants. Water from the Savannah River is used in the “park’s” heavy-water separation facility, which produces deuterium. In addition, the complex stores spent fuel rods from government research reactors and foreign reactors constructed by American corporations.

Comments: See article on waste disposal for information on other activities at the Savannah River Plant.

4. Pinellas Neutron Device Plant

Date built: 1956. Location: Just north of St. Petersburg, Florida, on the Pinellas peninsula on the Gulf of Mexico.

Operator: General Electric Company.

Employees: 1,200. Union representation:

None. Functions: Manufactures neutron generators for warheads.

Comments: In the manufacturing process, 285 workers are exposed to tritium, a radioactive substance impossible to contain. It eventually penetrates anything, and measurable amounts inevitably leak from the plant into the air and water of the surrounding community. Once in the body, tritium is chemically indistinguishable from hydrogen. General Electric officials at Pinellas say, “Tritium is nice to work with because of its half-life of only 12 years and because it can be flushed out of the body easily.” Workers who become “over-exposed” are sent home to drink beer and water.

Tags

Bill Ramsey

Bill Ramsey is the Peace Secretary for the American Friends Service Committee in the Southeast; he has been involved in research and organizing activities around the Pinellas and Oak Ridge Y-12 Plants. (1979)